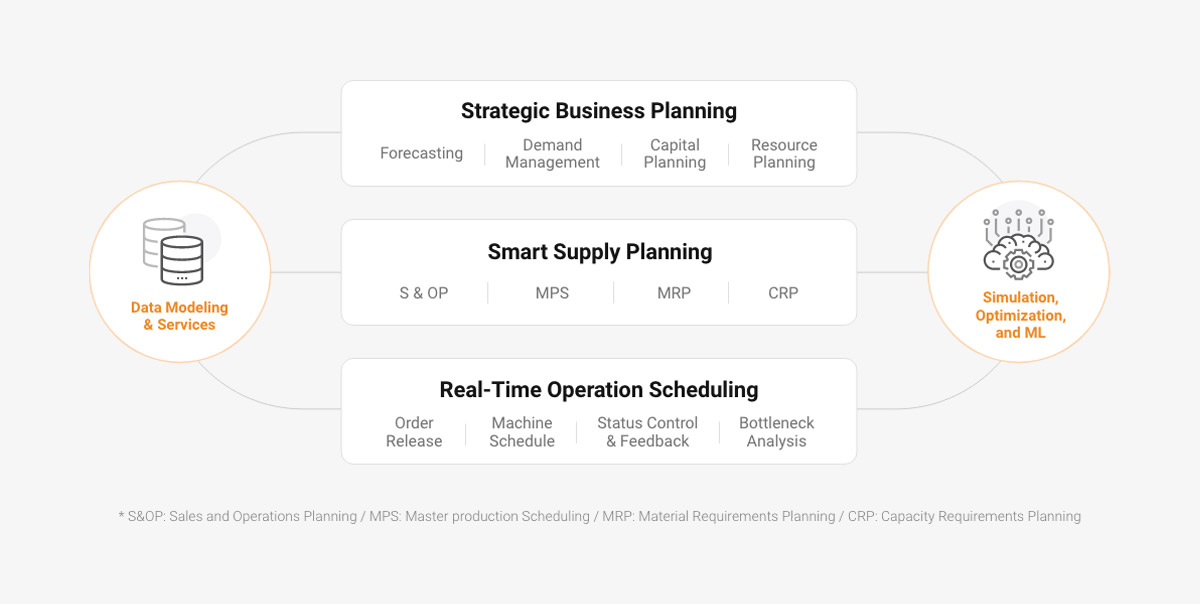

Production Planning

Companies spend a tremendous amount of time and effort forecasting future demand and allocating resources. It is critical to deploy an effective

simulation scenario that can anticipate all constraints and factors at a fast-paced environment. Our production planning modules create smart production plans that optimize sales and operations planning (S&OP) as well as capacity planning to include weekly and daily production plans.