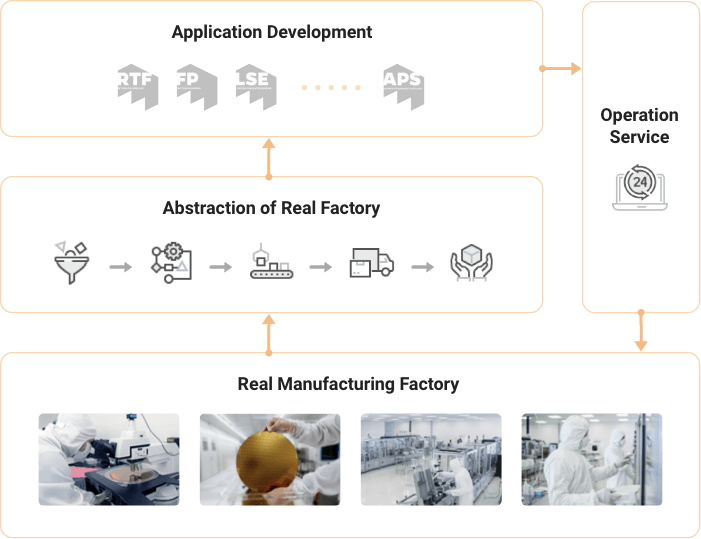

Data-driven simulation & ML-powered optimization

Create a simulation model that captures all rules and constraints with pre-built libraries. Our customized application runs with real-time data, producing accurate end results. Our simulation tool utilizes trained machine learning models for smart manufacturing operations.