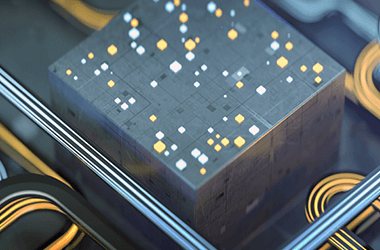

MOZART Fab WISE is a next-phase fab simulator for the semiconductor.

MOZART Fab WISE, built upon VMS's extensive 20-year expertise, is a solution that incorporates various specialized requirements arising from semiconductor and display manufacturing processes. It helps you tackle the intricate planning and scheduling challenges inherent to your fab operations, getting you closer to operational excellence.